Good Quality Dia 20mm

Basic Info.

| Model NO. | 20-160mm |

| Customized | Customized |

| Good Performance | High Quality |

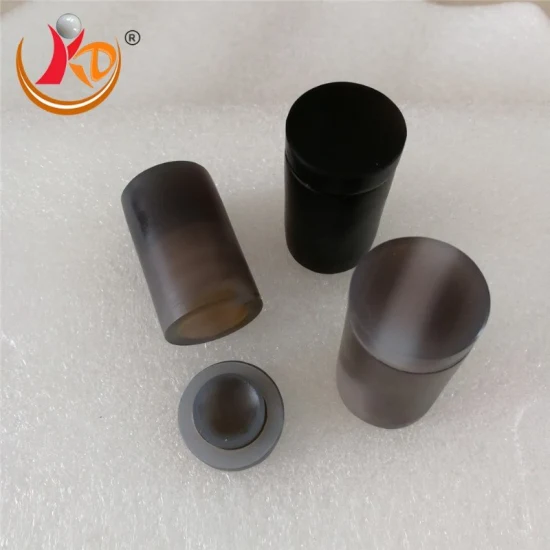

| High Heat Treatment Technology | for Zinc Mines |

| Good Wear Rate | for Sag Mills and Ball Mills |

| No Breakage | Tough Surface to Tough Core |

| Transport Package | Ton Bags or Steel Drums |

| Specification | ISO9001, SGS |

| Trademark | Taihong |

| Origin | Qingzhou, Shandong |

| HS Code | 732611 |

| Production Capacity | 100000tons/Year |

Product Description

Forged grinding balls

Chemical components

| Chemical Components | ||||||

| Type | Chemical components | |||||

| C | Mn | Si | Cr | S | P | |

| 45# | 0.42-0.48 | 0.50-0.80 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

| 50Mn | 0.48-0.56 | 0.70-1.00 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

| 60Mn | 0.57-0.65 | 0.70-1.00 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

| 65Mn | 0.62-0.70 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

| B2 | 0.75-0.85 | 0.70-0.90 | 0.17-0.37 | 0.40-0.60 | ≤0.030 | ≤0.030 |

| B3 | 0.55-0.65 | 0.75-0.90 | 0.20-0.37 | 0.85-1.20 | ≤0.030 | ≤0.030 |

| B4 | 0.58-0.66 | 0.65-0.80 | 1.60-1.90 | 0.70-0.90 | ≤0.030 | ≤0.030 |

| B6 | 0.97-1.03 | 1.00-1.10 | 0.20-0.30 | 0.50-0.60 | ≤0.025 | ≤0.025 |

| Mechanical Properties | ||||||||

| Material | Hardness(HRC) | Impact | Falling Times | |||||

| Φ20-Φ50 | Φ60-Φ90 | Φ100-Φ150 | ||||||

| Surface | Core | Surface | Core | Surface | Core | |||

| 45# | ≥54 | ≥36 | ≥54 | ≥34 | ≥52 | ≥30 | ≥15 | ≥22000 |

| 50Mn | ≥58 | ≥38 | ≥58 | ≥36 | ≥55 | ≥32 | ≥15 | ≥22000 |

| 60Mn | ≥60 | ≥42 | ≥60 | ≥40 | ≥58 | ≥36 | ≥15 | ≥22000 |

| 65Mn | ≥60 | ≥42 | ≥60 | ≥40 | ≥58 | ≥36 | ≥15 | ≥22000 |

| B2 | ≥60 | ≥60 | ≥60 | ≥50 | ≥60 | ≥46 | ≥15 | ≥22000 |

| B3 | ≥60 | ≥60 | ≥60 | ≥50 | ≥60 | ≥48 | ≥15 | ≥22000 |

| B4 | ≥60 | ≥60 | ≥60 | ≥55 | ≥60 | ≥52 | ≥15 | ≥22000 |

| B6 | ≥60 | ≥60 | ≥60 | ≥59 | ≥60 | ≥55 | ≥15 | ≥22000 |

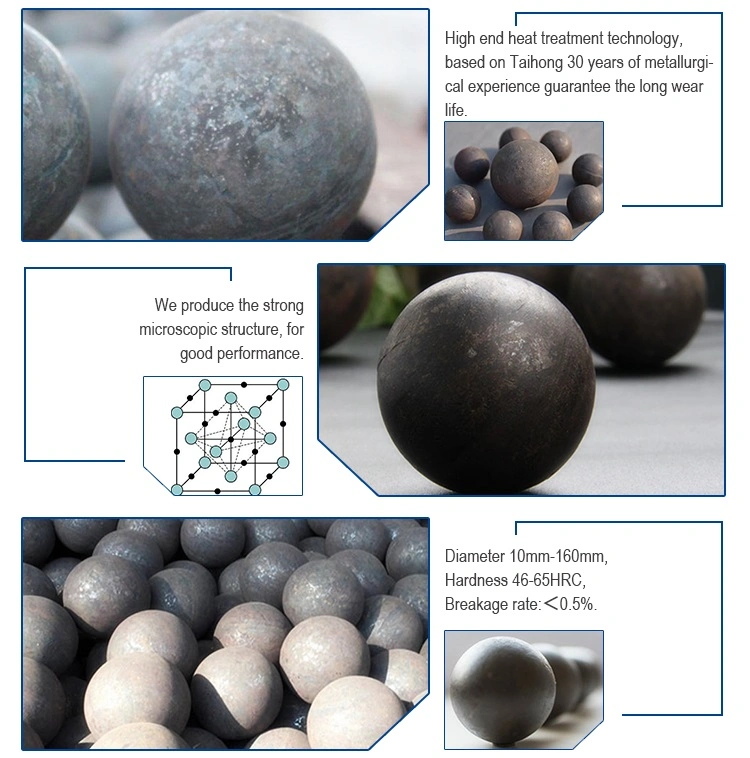

Hot Product

Testing

1. Certification

2. Testing Machine

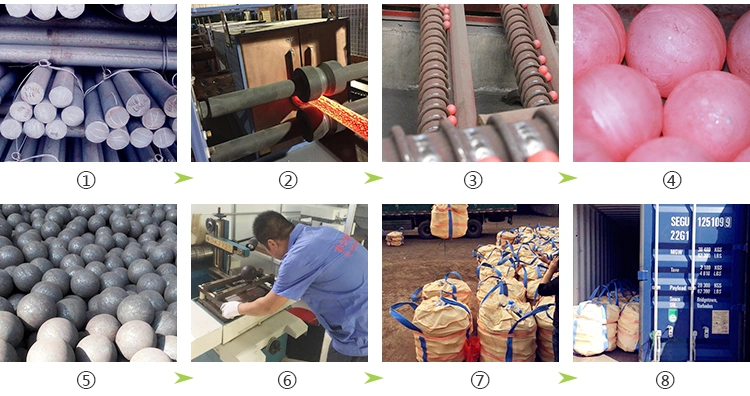

Production Line

Company Information

Welcome to Taihong, the leading manufacturer of steel grinding media, just like high chrome grinding balls, forged grinding balls, grinding rods, cylpebs and ball mill wear parts. Established in 1981, to serve the cement, mineral processing, power plant, chemical and other industries more than 30 years.

Grinding media is a valuable commodity widely used in cement production, mining industry-especially in gold, silver, copper and zinc mines, power stations for coal grinding, limestone grinding for flue gas desulphurisation, aerated building block manufacturing and so on.

We offer value for our customers through our qualified grinding products, professional service and dependable delivery.

Application

Packaging & Shipping

FAQ

1. Which kind of steel balls that you produce?

Our main products are high chrome cast grinding balls, forged balls, grinding cylpebs.

2. What's your warranty?

1 year.

3. Can you provide free sample?

Yes, we are glad to supply free samples which quantity is less than 10kgs. But usually the courier fee should be paid by customer.

4. How about your quality control?

In order to ensure the quality, we have strict quality control system.

a) We will test when purchase the raw materials.

b) We will test the products when finished.

5. What's your wear rate and breakage rate?

In different application areas, the wear rate is different. But the breakage rate is less than 0.5%.

6. Do you have any certificate?

Yes, our company has ISO 19001:2008 certificate.

We could also supply customer the Test report, SGS by third party.

Contact us