Tob 0.2

Basic Info.

| Model NO. | TOB-WXQM |

| Application | School, Lab, Lithium Ion Battery |

| After-Sales Service | 1 Year |

| Maximum Revolution | 35 ~ 335r/Min |

| Max. Rotation | 70~670 R/Min |

| Discharge Particle Size | up to 0.1 Microns Minimum |

| Motor Type | Electric |

| Rotationl Speed | 670r/Min |

| Motor Power | 0.75kw |

| Condition | New |

| Type | Planetary Ball Mill |

| Materials | Molybdenum |

| Transport Package | Wooden Boxes |

| Trademark | TOB |

| Origin | China |

| Production Capacity | 10000 Set/Month |

Product Description

0.2-4L Laboratory Small Horizontal Planetary Ball MillOverview

This TOB-WXQM planetary ball mill is an ideal equipment for scientific research units, institutions of higher learning, enterprise laboratory to obtain micro-particle research samples (each experiment can be obtained at the same time four samples). With functions of small size, full-featured, high efficiency, low noise. Equipped with vacuum ball milling tank, can be in the vacuum state of grinding samples. Widely used in geology, minerals, metallurgy, electronics, building materials, ceramics, chemicals, light industry, medicine, beauty, environmental protection and other departments. The rotational speed, the forward and reverse rotation time, and the total grinding time can be set according to the process requirements.

The advantage of horizontal planetary ball mill is that it can completely solve the phenomenon of material sinking, floating, sticking wall, etc., with better grinding effect, higher grinding efficiency and much better performance than the multi-directional planetary ball mill and double planetary ball mill on the market.

Working principle

XQM series frequency conversion planetary ball mill is equipped with four ball milling cans on the same turntable. When the turntable rotates, the ball milling cans revolve around the turntable axis and rotate around their own axis at the same time, making planetary movement. The grinding balls in the tank collide with each other in a high-speed motion, grinding and mixing the sample. The product can be used dry and wet two methods of grinding and mixing different particle size, different materials of the product, the minimum particle size of the grinding product can be up to 0.1 microns (1.0 x 10mm-4).Volume of grinding tank (L) | 0.05L ~ 1L * 4 | Transmission mode | gear transmission |

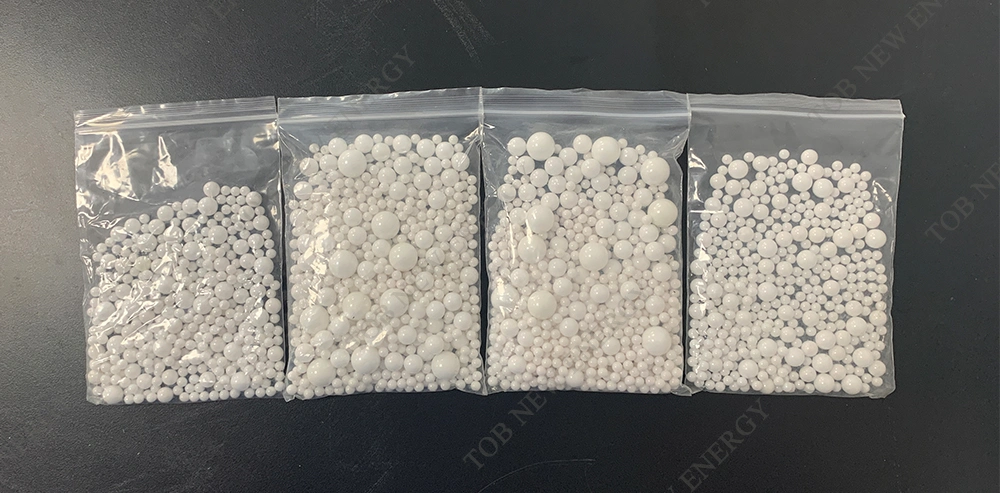

Grinding tank material | Nylon cans. Tungsten carbide tank. Stainless steel agate cans. Zirconia cans | Timing time | 1-9999 minutes |

Maximum charge per can | Material and grinding media do not exceed the 2/3 of volume | Alternate running timing time | 1-99 minutes |

feed particle size | Crunchy material less than 10mm Other less than 3mm | discharge particle size | Up to 0.1 microns minimum (depending on material crispness and process) |

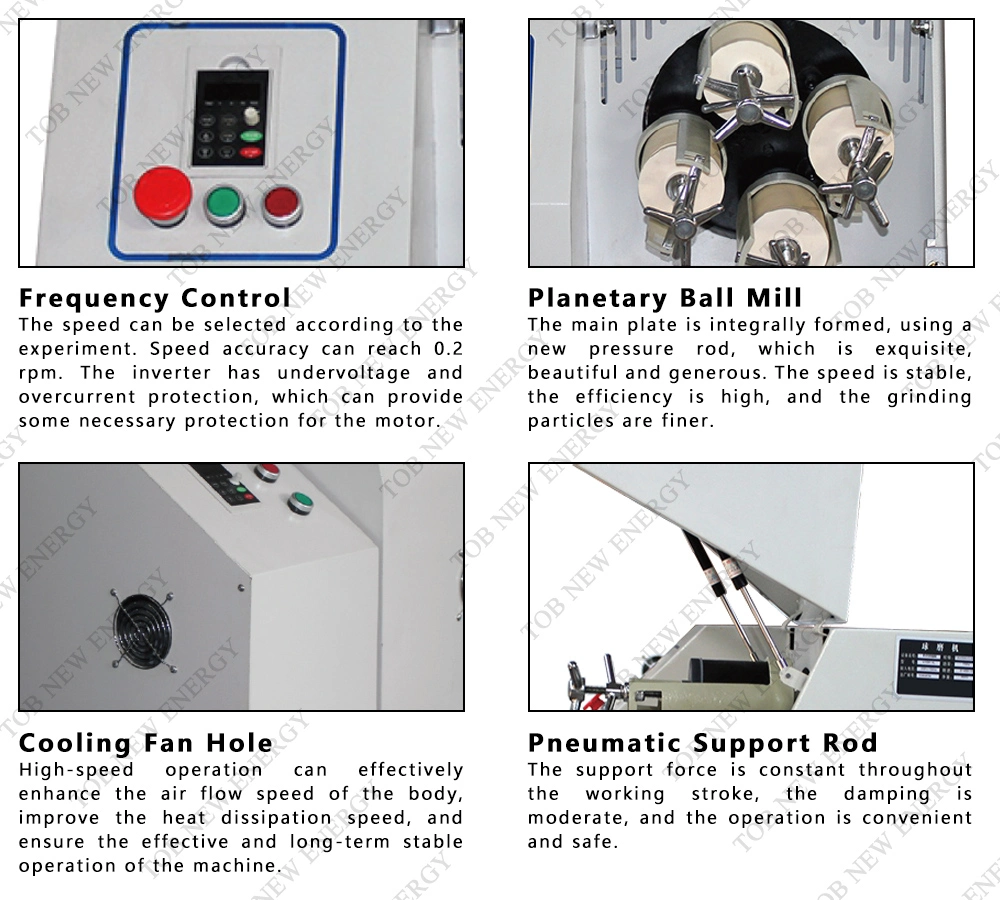

Speed | Maximum revolution 35 ~ 335r/min Max. rotation 70~670 r/min | Control operation mode | Variable frequency speed regulation and electronic timing control |

Operating voltage | 220V | Power | 0.75KW(WXQM-4A) |

Working mode | Two or four tanks working simultaneously | Continuous working time | 72 hours |

Product Features

- Gear transmission overcomes the shortcomings of the original belt drive, which is easy to slip and unstable.

- That is to maintain the stability of the gear drive, but also to overcome the original belt drive easy to slip, speed instability shortcomings.

- The ball milling tank adopts planetary motion, with high milling efficiency and fine particle size.

- Frequency conversion control, the ideal speed can be selected according to the test results.

- The inverter has undervoltage and overcurrent protection, which can perform some necessary protection for the motor.

- The whole body has the function of timing shutdown, automatic timing forward and reverse, and can freely choose one-way, alternate, continuous, timing and irregular operation modes according to needs, so as to improve the grinding efficiency.

- 4 kinds of samples with different sizes and materials can be obtained simultaneously in one experiment.

- Low center of gravity, stable performance, compact structure, convenient operation, safe and reliable, low noise, no pollution, low loss.

- The equipment is equipped with a safety switch, which can prevent the equipment from starting when the safety cover is opened, so as to avoid safety accidents.

- Because the horizontal planetary ball mill is a horizontal device, there is no fixed bottom surface when rotating, which better solves the problem of sinking some materials.